How Extrusion Blow Molding Differs From Injection Molding?

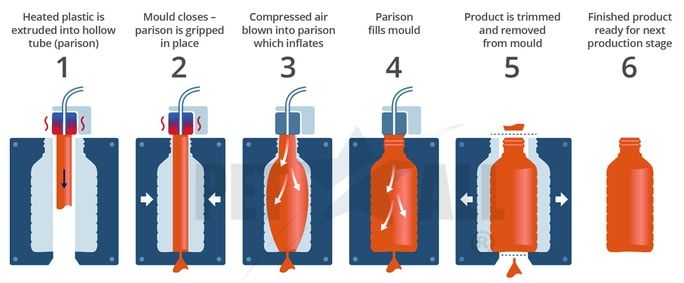

Extrusion blow molding (EBM) is a manufacturing process whereby plastic is melted and extruded (that is, expelled to form a shape) into a hollow tube; a form or mold. (At this point of the process this material is generally referred to as a “parison," which is a round melted mass that will then be molded; or formed.) The parison is held and sealed in the metal mold. Air is then blown into the mold thereby shaping it into the desired shape of the bottle or container. Once the plastic has cooled, the mold is opened and the part is discharged. There are two variations of extrusion blow molding: Continuous (with a constant extrusion of the parison) and Intermittent.

85 Royal Crest Court, Units 1 & 2 Markham,

Ontario, L3R 9X5

Phone: (905) 305-1797

Email: cmerrick@petallmfg.com